The shock news of Carillion going into liquidation will have made January a more sober month than usual for the many staff and suppliers who worked for Britain’s second biggest construction group.

The full facts behind the failure will come out in due course, but clearly several mitigating factors were the major contracts that were behind programme and haemorrhaging money. One obvious question that might be asked is – after the first project started going wrong, why were lessons not learnt?

This is not a paywall. Registration allows us to enhance your experience across Construction Management and ensure we deliver you quality editorial content.

Registering also means you can manage your own CPDs, comments, newsletter sign-ups and privacy settings.

Generally, people learn more when they fail than when they succeed – and that should be true of construction as well. Only they clearly don’t. Success is always celebrated and attributed to the right mindset, a great team or a clear plan, even if it is actually down to luck or good weather.

But fail, and the project team will usually want to walk away as quickly as possible without analysing why.

After Carillion’s experiences, and ultimate collapse, not to mention the Grenfell tragedy last year – perhaps construction should be more willing to face up to failure and why it happens, rather than shy away from it.

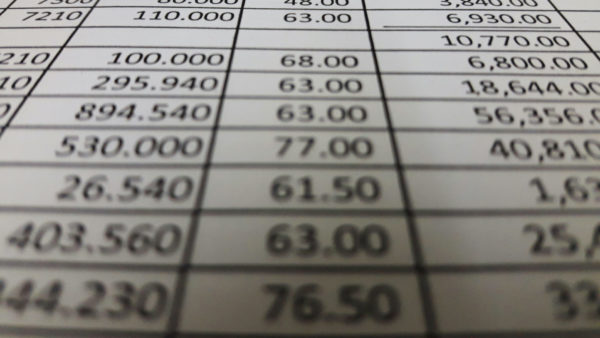

Although our industry is delivering performance improvements and better client satisfaction, we can’t be complacent. In fact, the UK Industry Performance Report 2017 confirmed that for construction projects:

- One-tenth resulted in poor client satisfaction;

- One-fifth suffered defects which adversely affect the project quality (nearly half with housing projects);

- One-third failed to meet their projected project costs (a quarter for housing);

- One-third were completed late; and

- Half were hampered by late design information.

So although projects fail quite frequently – by not meeting their aims – the industry seems reluctant to learn from its mistakes.

Contracts can be the tool by which we manage the relationship across the supply chain to encourage everyone to learn from, report, assess and embrace failure. A bit like the reinforced NEC4 early warning procedure. We should recognise the role of emotional intelligence: unless we start introducing processes to learn from failure, we won’t consistently create project success.

Sarah Fox is author and founder of contracts business 500 Words