Digital’s role in Seismic’s modular school building success

Completed earlier this year, the Seismic school building at the BRE Innovation Park in Watford is a successful demonstration of the benefits of modular construction. But digital had a role to play too.

It was manufactured and constructed in just 10 weeks, using a set of standardised components including steel frame, connector block, and wall, floor, ceiling and roof cassettes.

Part of the Transforming Construction Challenge, the building was delivered by the Seismic consortium of seven companies. These were: offsite manufacturers McAvoy and Algeco; Tata Steel; project management consultancy Blacc; the Manufacturing Technology Centre; the National Composites Centre; and Specific (part of Swansea University).

The consortium was created to develop design standardisation for schools to drive down costs, reduce lead times and radically improve productivity in offsite manufacturing processes.

Register for free or sign in to continue reading

This is not a paywall. Registration allows us to enhance your experience across Construction Management and ensure we deliver you quality editorial content.

Registering also means you can manage your own CPDs, comments, newsletter sign-ups and privacy settings.

Even against typical modular construction methods, Seismic’s results are impressive. Projects can be delivered up to 33% faster, with a 32% reduction in carbon and 47% better value.

Finding the right digital tools

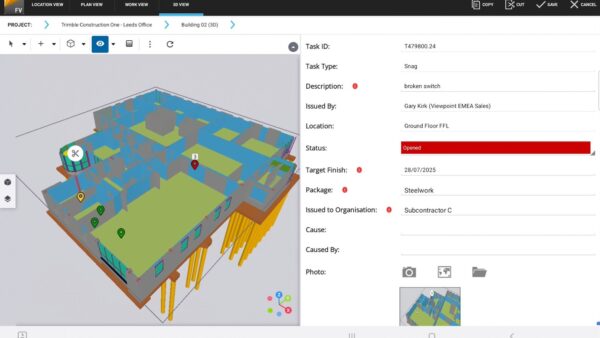

“It was essential to find a tool that would allow us to accurately develop the project in 3D from the outset and create the most intelligent and data-rich model we could.”

With Seismic’s programme divided into multiple work packages, McAvoy took on the responsibility of finding the best digital tools to help speed up the design and production process, and Archicad was chosen.

“We’ve been Archicad customers for around 15 years,” says Martin Harvey, head of design and technical services at McAvoy. “It was the best solution for us, allowing us to model designs in 3D before others were doing it. As a modular manufacturer, it was essential to find a tool that would allow us to accurately develop the project in 3D from the outset and create the most intelligent and data-rich model we could.

“With Seismic involving a completely new approach, it made sense to continue working with this tool.”

Working collaboratively

One of the challenges was finding the best way to work collaboratively, with each of the seven partners located in different parts of the UK. With most of the project taking place during the covid-19 pandemic, meeting in person was not an option.

McAvoy needed an easy way of sharing the designs with the wider project team during weekly Zoom calls. “Sharing of models in IFC format, federation of the models for clash detection along with using BIMx to present the models were essential for the project. It allowed us to easily communicate the design with all the consortium partners,” Harvey says.

“It was really effective in bringing both the technical and non-technical people in line on the project and helped everyone to understand the building inside and out.

“We looked at the model at least once a week. Because it’s so easy to toggle layers on and off, and view the building from any angle, inside and out, it became an effective way of checking and adapting the project as we went along.”

This use of the model was even extended to the wider marketing team as plans were developed to install an exhibition within the demonstrator building.

Seamless use

Harvey adds: “Anyone can use BIMx seamlessly – it doesn’t rely on expensive IT equipment or software. We used it to show the designers the interior and take measurements for the walls so that we could allocate space for the graphics.

“We even moved radiators, light switches and power sockets around in the model, collaborating in real-time, to increase wall space in certain parts of the building and ensure that the exhibition would work successfully.

“The whole project team was so familiar with the building that, when we walked in on launch day, there were no surprises.”

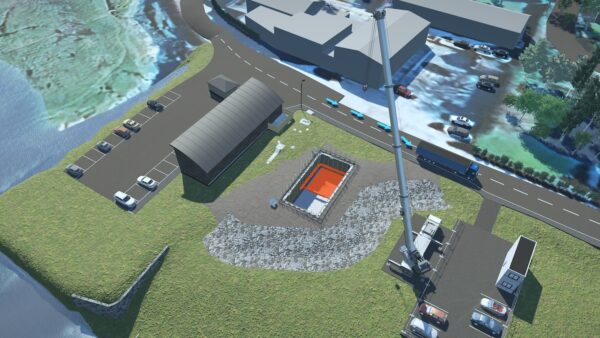

The demonstrator model was also used to explore the building in virtual reality. This allowed the design to be interrogated prior to manufacture. It also meant the model could be shown to users prior to visiting the real thing.

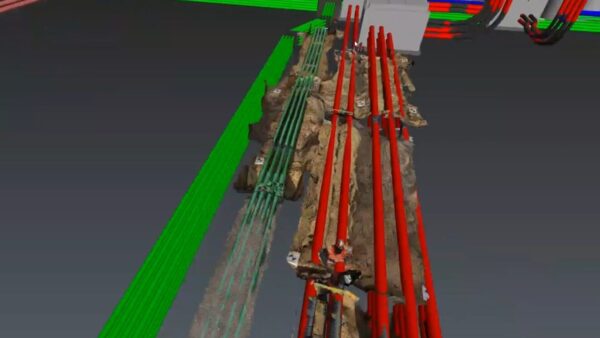

“The ability to toggle layers allowed us to do this for everything from the frame construction up to the M&E installation. It’s the quality of the model and the high level of data it contained that made this possible,” Harvey says.

Collaboration

He explains the importance of having a tool that can integrate seamlessly with other technology. “Algeco and Tata Steel both used different software, but it was never a problem because Archicad makes importing and exporting data so easy.

“It can pick up IFCs easily, federates with Tekla easily, which Tata Steel used to design the steel components, and doesn’t restrict us from using other tools. It is much more able to work in an open BIM environment compared with some other tools.”

The model was so well used by the project team that there was an unexpected outcome on launch day. “It was funny when we got on site with the final building. Everyone in the project team took the photo of the demonstrator from the same angle, which was the default angle that we started from every time that we loaded the model up,” Harvey reveals.

“You can get very polished visuals directly from the software and it really showed how accurate the render tool is. We were able to set the design model to the exact location coordinates using the Google Earth plug-in and also set the date and time within the model to accurately predict the sun location.

“The model is going to be used so that we can test taking it apart and rebuilding it. We’ll be able to track every element throughout its lifecycle.”

“When you compare the render with a photograph, even the shadows matched according to the time of day.”

Dealing with change

“Because it is a demonstrator building, we were changing things throughout the project as we were working towards the best example of the building,” Harvey says. “It meant lots of switching in of different objects. For example, when we made a change to the balcony, it was very easy to bring in the new solution and render different cladding options.

“The same is true on the M&E side, as we were working with new, innovative products to create the most sustainable and high-performance building that we could.

“It was so easy to bring these new objects in and we were able to create a model that is the exact representation of everything. It meant a level of familiarity before we’d even built it.”

The model is being kept up to date as one of the benefits of Seismic is that buildings can be dismantled and reassembled elsewhere. Or the components can be recycled and reused in other projects.

Harvey adds: “The model is going to be used so that we can test taking it apart and rebuilding it. And, because every component is tagged and linked to the model, we’ll be able to track every element throughout its lifecycle, making for a safer, easier to maintain building.”

Speeding up design

The ambition for the digital work section within the Seismic project was to get a digital version of the building that was as good as the physical construction at the end. Now, with a fully tested and completed project available, it is onto the next project, taking forward the lessons from Seismic.

Harvey concludes: “We have taken the learning from Seismic into one of our new offsite products and built our modules as objects within the software. Everything is set up to reflect our standards and the subcomponents that we use.

“We have a set-up that saves us significant design time, with hotlinks, automated scheduling and take-offs simplifying the process on larger buildings and making it quick and easy to create a unique building every time. It’s one of the key drivers of a platform-based approach – using repetition to improve the process and leave time for delivering more added value in projects.”

Don’t miss out on BIM and digital construction news: sign up to receive the BIMplus newsletter.